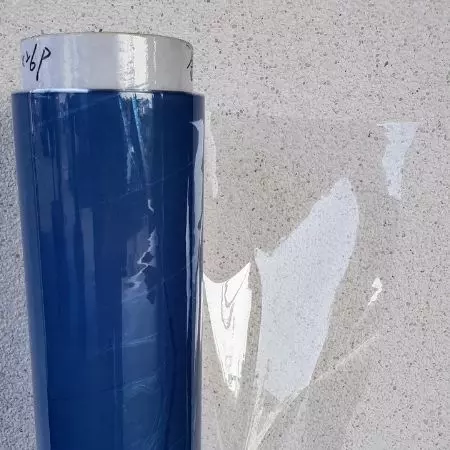

Cold Crack Resistent PVC Sheeting

Cold crack resistance soft PVC sheet is the ideal material for the application operating under the low temperature environment.

In average, standard PVC sheet without additives could work under the condition above 1 °C (33°F ) or the material will degrade and start to brittle and crack. The important advantage of Polymer especially Polyvinyl Chloride (PVC) is the high degree of customization. By adding cold-crack additives, PVC sheet could stand in extreme conditions up to 25°C . Depending on material hardness, the maximum cold crack durability will be adjusted accordingly.

Our PVC sheet could be tailored made to meet the testing standard, ASTM D-1790 so it wouldn’t crack or fracture easily in the low temperature environment. You could upgrade Normal Clear, Super Clear, Laminated Thick PVC sheet with cold-crack additives to optimize material durability.

The cold resistance flexible PVC sheet most commonly are used in cold climate area (eg., America, Canada, Romania, Russia) or in the environment where the temperature are usually under zero degree (eg., cold room).

ISO 140001, ISO 9001 D&B and TÜV Rheinland Certified Manufacturer

With over 30 years of experience in plastic vinyl industry, we have a group of experienced sales, R&D and production team to help you find the mating material for your applications.

PVC Sheet Features

- Good Cold Resistance

- Good Dimensional Stability

- Waterproof

- Resistant to acid & alkali

- Flexibility

- Easy Maintainance

Processing Methods

- High-Frequency Welding,

- Ultra-Sonic Welding,

- Sewing,

- Printing,

- Adding Adhesive,

- Laminating.

Specification

| Material | 100% PVC raw material + Cold Crack Additive |

|---|---|

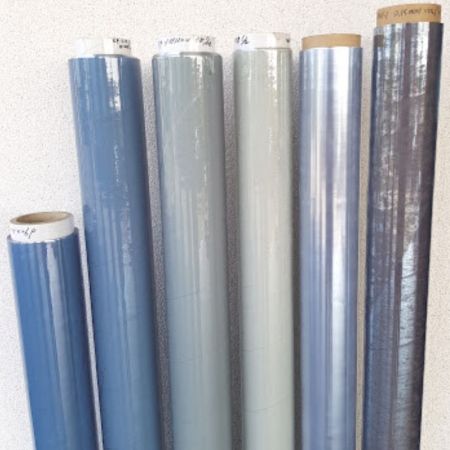

| Color | Customize ( Transparent, Transparent Color, Translucent) |

| Grade | Customize (Normal Clear, Super Clear, Textured Embossing) |

| Thickness (Gauge) | Normal Clear Grade 0.05-0.5 mm |

| Super Clear Grade 0.15-6 mm | |

| Textured 0.15-3 mm | |

| Packaging | Rolls, Wrap in opaque plastics PVC sheet. Check other packaging options here. |

| Width per Roll | 30"-72" inch |

| Weight per Roll | 25 kg + |

| Hardness | 27-55 phr* |

| Recyling | #3 |

| Test Compliance | EN71I |

| Optional Qualifiation | US FMVSS 302, NPFA701(Method #1), France Class M2REACH, RoHS, Non-Phthalates (Phthalates Free, Non-P), CPSIA, CHCC, etc. |

| Add-in(Customize) | Anti-UV, Anti-Mold or Anti-Mildew, Low Toxic, Fire Retardent (FR) etc. |

*phr (aka parts per hundred resin) indicates the amount of plasticizer added to the material. The higher the phr, the softer and more flexible.

PVC Applications

- Strips,

- curtains,

- Marquee & Tent window,

- Inflatables,

- Table Covers,

- Boat windows,

- Outdoor enclosures

Packing PVC Sheet Rolls

We offer following packaing options for your PVC sheet rools:

- Standard Packaging: Wrap with Opaque PVC Sheets

- Sponge +Opaque PVC sheet

- Cartons

- Craft Paper

- Pallets

- Pallets with Cartons

- Pallets with Craft Paper

- Pallets with Concaves

- Vertical Pallets

- Wooden Box

- Suspended Wooden Box

For other special packaging not mentioned above, please contact our sales team.

- PVC Sheet Applications

- About SKP

- Product Brochure

PVC Plastic Sheets Catalogue - 2020

Learn how flexible PVC sheets is the desirable waterproof material for your next applications.